Non Woven Binder Fabric

Fabric properties of Non woven Binder vary from crisp to that soft-to-the –touch to harsh, impossible-to-tear to extremely weak. They consider that merchandise must be secure for each septic and sewer methods .

Orange County Sanitation District has created a crusade, “What 2 Flush”, which recommends flushing only the”three P’s — pee, poop and paper” Geocomposite drain consisting of needle-punched nonwoven filter and carrier geotextiles of polypropylene staple fibers every having a mass per area of 200 g/m².

Hydrosize® CarbonSizing options designed to be use in the manufacturing of glass fiber, carbon fiber and pure fiber.Nonwoven binder & Specialties deals with numerous software fields, together with wall cowl, filtration, wipes and glass fiber.

One dispersion can typical be use for multiple applications to satisfy the particular needs.

Spun bond has been mix with melt-blown non woven , conform them right into a layer product known as SMS ( spun-melt- spun).

They’re flat or tuft pervious wastes that are made incontinently from separate fibers, molten plastic or plastic film. They aren’t made by weaving or stitch and don’t bear converting the fibers to yarn.

Typically, a sure share of recycle materials and oil-based materials are utilize in nonwoven fabrics. The percentage of recycled materials varies based mostly upon the energy of fabric needed for the precise use.

As a high stiffness binder for carpet again coating, interlinings, to offer stiffness to Non woven binder materials to make shoe parts viz upper soles. Flashspun materials are create by spraying a dissolved resin right into a chamber, where the solvent evaporates.

In the last case, only 10 bags out of forty eight, 000 were broken despite a excessive set up rate of 700 bags per day. DigiGuard® IJWater-based overprint coatings enhance sturdiness and enhance the look & feel of inkjet-printed materials.

Fibers are first spun, cut to some centimeters size, and put into bales.

The chief filaments are also blend,” opened”in a multistep course of, dispersed on a conveyor belt, and spread in a invariant internet by a wetlaid, airlaid, or carding/ crosslapping course of.

Wetlaid operations generally use zero.25 to 0. seventy five in (0.64 to1.91 cm) lengthy filaments, still generally longer if the fiber is stiff or thick. Airlaid processing generally uses0.5 to four.0 in (1.3 to10.2 cm) filaments.

Considering the environmental aspect now a days non woven binder materials are getting prefer in the packaging business as well for number of purposes instead of polyethylene material

This exploration consists of printing of needle punchednon-woven viscose rayon fabrics meaning the ease of operation of colors for achromatism of cloth substrates.

The viscose non woven fabrics have been print with pigment utilizing binder by varying the pigment to binder ratio and polymerizing was carrier out at two totally different temperatures. The prints had been examine for color yield and rubbing fastness properties (dry & wet).

It was notice that with rising the concentration of binder the depth of the pigment prints will get elevate also the fastness properties get improve.

Our comprehensive lab setting allows us to test, evaluate, regulate, and run check batch and mock production formulations, saving working costs and reducing waste.

This provides our customers the peace of mind that the non woven binder and textile binders purchased from JATKO perform consistently at an optimal degree.

OC-bio binder™ is fiber-binding system based mostly on modified biopolymers and pure plant compounds.

It is classified as non-irritating and non-dangerous to the surroundings by the European REACH regulations, and due to this fact enables the manufacturing of more sustainable fiber-based supplies.

In addition, some non woven materials can be recycle after use, given the correct treatment and amenities. JATKO manufactures water-based performance remedies, including nonwoven binders and textile binders formulated to customer specifications.

Binders improve the performance features of non woven and woven textiles, similar to growing stability in the product dimension, fraying prevention, and material stiffness.

Most generally, these binder applications are discover in the textile, paper, and nonwoven markets.

JATKO has developed products for specific coating functions, together with spray, direct fleece, froth fleece, niche, and print coating.

Table number 3 indicates the impact of binder to pigment ratio and temperature on rubbing fastness properties of Red pigment.

We provide binders used in the processing of nonwoven rolled items manufactured from materials including polypropylene, polyester, nylon and glass.

In different words non woven cloth may be simply define as a fabric these could be produce by quite so much of processes aside from weaving and knitting.

The wastewater industry is encouraging a standard definition of flushability, including dispersibility, and third-party assessment or verification, such as by NSF International.

Melt-blown nonwovens have extraordinarily fine fiber diameters but aren’t robust materials. SMS accoutrements, made fully from PP are water-repellent and nice enough to serve disposable fabrics.

Melt-blown is usually use as filter media, with the ability to capture very nice particles. Regarding the bonding of Spunlaid, Rieter has launched a brand new generation of nonwovens called Spunjet.

This results in a variety of finish merchandise similar to nappies, filters, teabags, geotextiles, and so forth. a few of that are sturdy and others are disposable.

The packaging material manufacture from non woven may be made enticing by printing process.

The color energy (K/S values) of pigment prints was measure on Macbeth laptop color matching system and Rubbing fastness of the prints was assesses on Crock meter.

Nonwoven fabrics are finagle accoutrements which could be single- use, have a limited life, or be veritably durable.

These properties are often mix to create fabrics suite for particular jobs, whereas attaining an excellent steadiness between product use-life and price.

They can mimic the appearance, texture and strength of a woven cloth and can be as bulky as the thickest paddings.

Melt-blown non woven are produce by extruding melt polymer fibers through a spin web or die consisting of up to 40 holes per inch to type long skinny fibers that are stretch and cooled by passing scorching air over the filaments as they fall from the bones.

The resultant web is collect into rolls and subsequently converted to completed merchandise. The extraordinarily fine fibers differ from other extrusions, notably spun bond, in that they’ve low intrinsic power but a lot smaller size offering key properties.

One of the biggest customers of SM and SMS supplies is the disposable diaper and female care trade. The dry and moist rubber fastness properties of pigments have been additionally found improve with rising pigment to binder ratio.

Non woven binder fabrics are broadly outline as sheet or internet structures bond together by entangling fiber or filaments mechanically, thermally or chemically.

In fact, Spunjet is the bonding of the Spunlaid filaments due to the hydroentanglement.

Since pigments do not have affinity for textile substrate those are certain with textile substrate with the help of binder.

Binder truly holds the pigment particles and sandwich it between cloth surface and its transparent three dimensional polymeric elastic movie which is formed throughout polymerization at elevate temperature.

Similar pattern was notice within the case of moist rubbing fastness at all pigment concentration ranges.

The first stage in the manufacturing process of nonwoven fabrics is “ product of web” and another is “ cling of internet by exercising several styles”.

Non woven material has greater share in market and contemplate the environmental side it’s thought of as substitute for plastic packaging materials.

They are essentially, insoluble within the media into which they’re include, and are mechanically dispersing there to find a way to modify the color and lightweight scattering properties of such media.

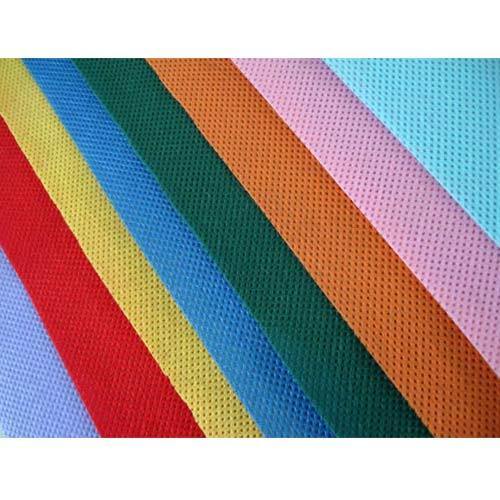

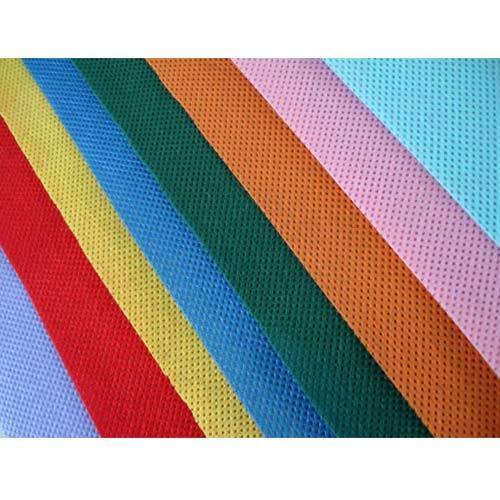

HERE IS EXAMPLE OF Non Woven Binder Fabric

They additionally encourage clear marking of non-flushable merchandise as “No Flush” together with creating a “No Flush” logo. NurtureYield®Advanced supplies designed to boost the efficiency and processing of agricultural products.

Water-compatible curing agents include aliphatic amines, cycloaliphatic amines and dicyandiamide. Library paste catalysts, correspond to tertiary amines and imidazole composites, may be use.

Some of those are felting, tenacious cling, thermal cling, sew cling, needle punching, hydro- trap and spin laying.

Conventional binders are generally made of petroleum-ground substances (e.g. paints), indeed though the filaments could also be fully from renewable cellulose.

In addition to binder another element can additionally be add to the textile pigment printing paste and that is call fixer.

Fixers are mostly urea formaldehyde pre-condensates which assist in bettering rubbing fastness of pigment by strengthening of binder cross hyperlinks to carry pigment on the textile substrate.

Non woven binder can also begin with films and fibrillate, serrate or vacuum-form them with patterned holes. Wet laid mat or” glass towel” use wet- diced, heavy denier filaments in the 6 to twenty micro meter periphery range.

Honey downgraded mats or”batts” use spastic fantastic denier filaments within the zero.1 to 6 vary. The ultimate is similar, however run at much advanced temperatures, to melt-blown thermoplastic nonwovens binder.

The OC-biobinder™ system can be utilize on woven textiles to increase stiffness and forestall fraying making it appropriate for the manufacturing of solar blinds.

On nonwoven or air-laid materials, OC-bio binder™ can enhance tensile strength, decrease linting and improve dimensional stability.

The system is appropriate with most types of fibers, including cellulose-based fibers (e.g. cotton, paper pulp), synthetic fibers (e.g. polyester, PLA), mineral fibers (e.g. glass fibers) and mixed fibers.

Table number 2 signifies the impact of binder to pigment ratio and temperature on colour strength of Blue pigment. Table no 1 indicates the impact of binder to pigment ratio and temperature on colour strength of Red pigment.

Some non woven binder materials lack adequate power except densified or bolstered by a backing. In recent years, non-wovens have turn out to be an various to polyurethane foam.

Hi tech product for carpet backing, waddings with high filler loading capacity gives medium onerous to onerous finish and glorious moldability where required.