Tips for Pearl Paste

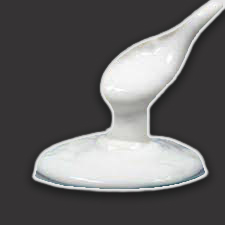

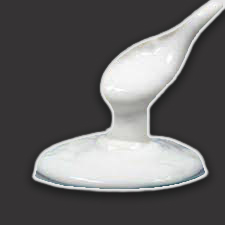

Pearl Paste is a water-based printing base that is used in textile printing to generate an elastic and hence contact pearl effect. It is simple to use when printing.

It is recommended to repair since the dry-wet rubbing and washing fastness is excellent.

Advantages of Pearl paste

- It is simple to use when printing.

- It is recommend to repair since the dry-wet rubbing and washing fastness are both excellent.

- It’s set at (280°F/140°C) for 2 minutes and (320°F/160°C) for 1,5 minutes.

- Compliant with environmental regulations.

Applications

- Rubbing and washing tests should be applied 24 hours after usage to create elastic and hence contact pearl effect in textile printing.

- To minimise viscosity, never use water. Please thoroughly mix the product before using.

- Avoid using any additions that aren’t recommended.

- The screen should be cleaned with water and a sponge after each use.

- It is used in textile printing to generate an elastic and hence touching pearl impression.

To know more Chemical